Saatgut Verarbeitung

Saatgut Verarbeitung

Der Weg von der Saatgutverpackung bis zur Aussaat ist heikel. Die Luftentfeuchter von Industrial kontrollieren sorgfältig die Feuchtigkeit und sorgen dafür, dass das Saatgut gesund bleibt und ein starkes Wachstum ermöglicht.

Systeme zur Entfeuchtung und Temperaturkontrolle für die Saatgutaufbereitung

Unsere industriellen Luftentfeuchter

Adsorptionstrockner Bulkserie – Adsorptionstrockners

Klein, leicht und robust – Die angebotene Serie von Adsorptionstrocknern besteht aus mehreren kleinen, leichten und energieeffizienten Modellen, die speziell für kleinere oder temporäre Lösungen.

Die Entfeuchter haben ein robustes Standard-Edelstahlgehäuse und verwenden einen Ventilator für Prozess- und Regenerationsluft.Produkt ansehen

- Prozessluft 150 – 400 m³/h

- Entfeuchtungsleistung bis zu 1,5 kg/u

- 480 mm x 420 mm x 415 mm

Die Entfeuchter haben ein robustes Standard-Edelstahlgehäuse und verwenden einen Ventilator für Prozess- und Regenerationsluft.Produkt ansehen

Adsorptionstrockner 500 – Adsorptionstrockners

Standardmäßig ist dieser Lufttrockner mit einem robusten Edelstahlgehäuse ausgestattet, optional mit energieeffizienten EC-Ventilatoren von hoher Qualität und geringem Energieverbrauch.

Der Lufttrockner erfordert nur sehr wenig Wartung, dennoch ist er so konzipiert, dass er leicht zugänglich ist, damit die verschiedenen Komponenten angemessen überprüft und gegebenenfalls schnell ausgetauscht werden können. Produkt ansehen

- Prozessluft 150 – 500 m³/h

- Entfeuchtungsleistung bis zu 6 kg/u

- 540 mm x 760 mm x 1100 mm

Der Lufttrockner erfordert nur sehr wenig Wartung, dennoch ist er so konzipiert, dass er leicht zugänglich ist, damit die verschiedenen Komponenten angemessen überprüft und gegebenenfalls schnell ausgetauscht werden können. Produkt ansehen

Adsorptionstrockner 1000 – Adsorptionstrockners

Standardmäßig ist dieser Trockner mit einem robusten Edelstahlgehäuse ausgestattet, optional mit energieeffizienten EC-Ventilatoren von hoher Qualität und niedrigem Energieverbrauch.

Sehr geringer Wartungsaufwand, leicht erweiterbar mit Wärmerückgewinnung oder Kühl-/Heizwasserblöcken zur optimalen Regelung der Prozesslufttemperatur.Produkt ansehen

- Prozessluft 500 – 1000 m³/h

- Entfeuchtungsleistung bis zu 6 kg/u

- 540 mm x 760 mm x 1100 mm

Sehr geringer Wartungsaufwand, leicht erweiterbar mit Wärmerückgewinnung oder Kühl-/Heizwasserblöcken zur optimalen Regelung der Prozesslufttemperatur.Produkt ansehen

Adsorptionstrockner 4000 – Adsorptionstrockners

Der Adsorptionstrockner 4000 ist standardmäßig mit einem robusten Edelstahlgehäuse ausgestattet, optional mit energieeffizienten, hochwertigen EC-Ventilatoren mit geringem Energieverbrauch.

Er ist eine komplette Einheit mit Rotor, Getriebemotor, Ventilatoren, Heizung, Luftfiltern und integrierter Elektrik mit allen für den sicheren Betrieb notwendigen Komponenten.Produkt ansehen

- Prozessluft 1000 – 4000 m³/h

- Entfeuchtungsleistung bis zu 20 kg/u

- 825 mm x 1640 mm x 1725 mm

Er ist eine komplette Einheit mit Rotor, Getriebemotor, Ventilatoren, Heizung, Luftfiltern und integrierter Elektrik mit allen für den sicheren Betrieb notwendigen Komponenten.Produkt ansehen

Adsorptionstrockner 10.000 – Adsorptionstrockners

Der Adsorptionstrockner 10.000 ist der größte „Standard“-Trockner der Produktreihe. Ausgestattet mit energieeffizienten EC-Ventilatoren von hoher Qualität und niedrigem Energieverbrauch.

Der Adsorptionstrockner 10.000 hat eine Entfeuchtungsleistung von 25 Litern bis über 60 Litern pro Stunde.Produkt ansehen

- Prozessluft 4000 – 10.000 m³/h

- Entfeuchtungsleistung bis zu 60 kg/u

- 2080 mm x 1360 mm x 2160 mm

Der Adsorptionstrockner 10.000 hat eine Entfeuchtungsleistung von 25 Litern bis über 60 Litern pro Stunde.Produkt ansehen

Kondensationstrockner (Custom) – Kondensationstrockner

Der Kondensationsentfeuchter erreicht eine sehr niedrige Luftfeuchtigkeit, wobei der Entfeuchter so optimiert ist, dass er möglichst wenig Energie verbraucht. Der Luftentfeuchter ist besonders energieeffizient bei sehr heißer und feuchter Luft, die leicht kondensiert. Produkt ansehen

Hybride Trockner (Custom) – Hybride Trockners

Der Hybrid-Luftentfeuchter eignet sich hervorragend für Prozesse mit maximalen Trocknungstemperaturen. Der Luftentfeuchter verfügt über mehr Restwärme als die Kondensatorwärme allein und ist vollständig auf minimalen Energieverbrauch optimiert.

Der Schrank besteht aus einem robusten Stahlrahmen mit Aluminium-Gehäuseprofilen. Bei dem die doppelwandigen und isolierten Paneele aus verzinkten und pulverbeschichteten Blechen bestehen. Der Hybrid-Luftentfeuchter ist mit Beutelfiltern der Klasse EU7 ausgestattet, um die internen Komponenten zu schützen und ein schnelles Verschmutzen des Rotors zu verhindern, damit die Trocknungskapazität intakt bleibt. Produkt ansehen

Der Schrank besteht aus einem robusten Stahlrahmen mit Aluminium-Gehäuseprofilen. Bei dem die doppelwandigen und isolierten Paneele aus verzinkten und pulverbeschichteten Blechen bestehen. Der Hybrid-Luftentfeuchter ist mit Beutelfiltern der Klasse EU7 ausgestattet, um die internen Komponenten zu schützen und ein schnelles Verschmutzen des Rotors zu verhindern, damit die Trocknungskapazität intakt bleibt. Produkt ansehen

Unsere Gewächshaussysteme

Doppelte Luftverteilungsschläuche (⌀ 470 mm bis 940 mm) – Gewächshaus

Enerdes hat ein Luftverteilungssystem entwickelt, das die Gewächshäuser weltweit verändert hat. Unser Vermächtnis umfasst eine große Anzahl von Patenten in der Gewächshaustechnologie, darunter das doppelte Luftverteilungsschlauch.

Produkt ansehen

- Unvergleichliche Gleichmäßigkeit beim Pflanzenwachstum.

- Außergewöhnlich konsistente und zuverlässige Ertragsraten.

- Anpassbare Endkappen für bessere Pflanzenqualität in Mittelgängen und bessere Arbeitsbedingungen.

Produkt ansehen

Lüftungsgerät (kundenspezifisch) – Gewächshaus

Enerdes bietet spezielle Klimageräte für Gewächshäuser an. Unsere Geräte sorgen für eine optimale Klimakontrolle, indem sie Temperatur und Feuchtigkeit präzise ausgleichen.

Produkt ansehen

- Effizienter Betrieb sowohl in begrenzten als auch in ausgedehnten Gewächshausräumen.

- Entwickelt für optimale Leistung in unterschiedlichen Klimazonen, von milden bis hin zu extremen Bedingungen.

- Eine fortschrittliche, benutzerfreundliche Steuerungsschnittstelle, die eine präzise Anpassung an unterschiedliche Größen, Bahnlängen und Umgebungsbedingungen in Gewächshäusern ermöglicht.

Produkt ansehen

Abluftventilatoren (AC-Ventilatoren) – AC-Ventilatoren

AC-Ventilatoren eignen sich hervorragend für die Frischluftzufuhr in den Anbaubereichen Ihres Gewächshauses und verbessern sowohl den Komfort als auch die Effizienz Ihres landwirtschaftlichen Betriebs. Diese Ventilatoren spielen eine entscheidende Rolle bei der Steigerung der Qualität und Produktivität Ihres Gewächshausbetriebs. Für zusätzliche Funktionalität können diese Geräte mit automatisch selbstschließenden Lamellen ausgestattet werden. Diese Lamellen öffnen sich nahtlos, wenn der Ventilator aktiviert wird, und sorgen für eine effiziente Luftregulierung. Produkt ansehen

EC-Ventilatoren (Axialströmung) – EC-Ventilatoren

Die auf Energieeffizienz optimierten EC-Axialventilatoren eignen sich hervorragend für großvolumige Umgebungen mit niedrigem Druck wie Gewächshäuser.

- Sie sind so konzipiert, dass sie die Luft parallel zu ihrer Welle bewegen und eignen sich daher für große Räume.

- Entwickelt für Kühlung, Belüftung und effektive Luftzirkulation.

- Kann von unseren Experten an die spezifischen Anforderungen Ihres Projekts angepasst werden.

EC-Ventilatoren (Radialströmung) – EC-Ventilatoren

Radiale EC-Ventilatoren sind eine ideale Lösung für Gewächshäuser, da sie durch die radiale Luftumwälzung eine gleichmäßige Luftverteilung gewährleisten.

- Erzielen Sie eine gleichmäßige Luftverteilung in Räumen jeder Größe.

- Sie sind mit energieeffizienten Motoren ausgestattet, die den Stromverbrauch erheblich senken.

- Bieten Kosteneinsparungen gegenüber herkömmlichen Ventilatoren mit einfacher, präziser Steuerung für verschiedene Gewächshausgrößen und -bedingungen.

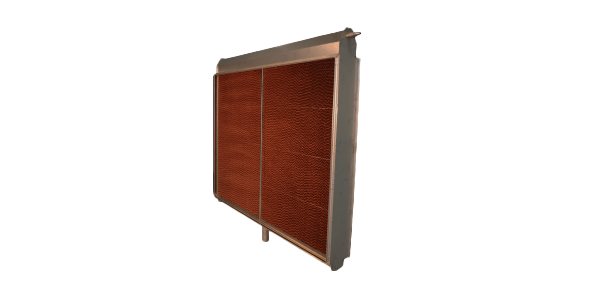

Kühlpads: Lüfter und Pad-Kühlsystem – Gewächshaus

Wenn Außenluft angesaugt wird, ist die Verwendung von Kühlmatten der effizienteste Weg, um das Gewächshaus zu kühlen. Durch den Einsatz von Kühlpads kann die Umgebungstemperatur deutlich gesenkt werden.

- Lange Produktlebensdauer

- Verwendung von Rahmen zur Erhöhung der Stabilität

- Universell einsetzbar

- Geringe Wartung

- Umweltfreundlich

Beratung anfordern

Oder rufen Sie uns an

Klimalösungen für Ihre Saatgutfarm

Klimalösungen für Ihre Saatgutfarm