Greenhouse heating and CO2 enrichment for plant health

An adequate heating system is one of the most important components in a successful greenhouse. In order to grow quality crops with a profit, it is essential that the heating system in your greenhouse is energy efficient and robust.

On top of that air quality is very important for your crops. Part of this is the CO2 concentration in your greenhouse. You can increase the CO2 level in your greenhouse with a CO2 enrichment system. This is beneficial for plant growth and crop yield. At Enerdes we can develop systems that fully integrate heating and Carbon Dioxide enrichment for your greenhouse, saving you a lot of costs.

It is essential to maintain the optimal temperature in your greenhouse for your plant health and growth. Creating a homogeneous temperature distribution in all areas and corners of your greenhouse is beneficial for high quality plants and a high crop yield.

However, if you do not have a proper lay-out of your greenhouse heating system, it can become very costly to obtain the right temperature. On the other hand, an inferior heating system can lead to crop losses. Some areas may become too hot, others may stay too cold. Plants in different areas of the greenhouse will show different growing rates. Temperature differences will also lead to absolute humidity differences. Consequently, plant diseases and mold development may occur in some areas if heating and cooling systems do not operate adequately.

Temperature controlled greenhouse

In very few climates, it is sufficient to heat your greenhouse with solar energy. In sunny seasons the sun will provide enough light and radiation to heat the greenhouse to the desired temperature. However, in colder seasons like the winter period or during nights, it may be necessary to have additional heating in your greenhouse.

Temperature control is a major component of the greenhouse climate control system.

Greenhouse heating in the winter

Much additional heating may be required if your greenhouse is located in a climate with serious winter weather.

Depending on your crop type, the allowed minimum temperature in your greenhouse is determined. With this and your greenhouse type and the greenhouse volume, the required heating system is determined and dimensioned.

Greenhouse snow proof

In climates with regular snowfall, snow protection can be included. A snow-tube circuit is integrated in the heating system, and placed on top of the greenhouse.

With a dedicated snowmelt system, the snow is melted from the greenhouse roof, without having to open the vents. Snow no longer blocks the light, and your plants can happily grow.

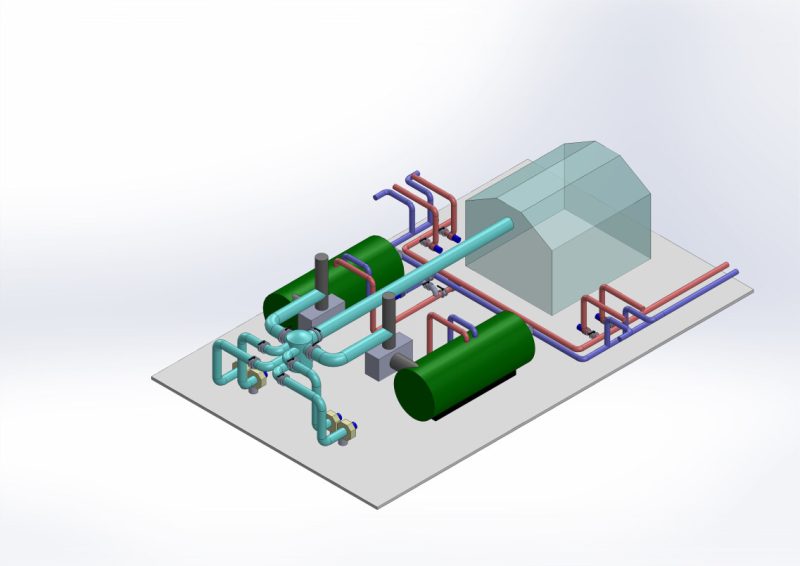

Greenhouse with Boiler Room

Boiler rooms serve to heat the greenhouse, produce CO2, store heat and produce steam for disinfecting material. The boiler room must comply with legal requirements and guidelines.

Many different installations are placed in the boiler room, many of which are dependent on each other and therefore need to be properly coordinated. For example, there are boilers in the boiler room, with flue gas condensers if necessary. But also a CO2 installation, main distribution lines and group divider are often part of a boiler room.

The boilers are used for heating the greenhouse, producing CO2, and possibly steam. A boiler is dimensioned to meet the required heat demand, which is determined by a climate analysis. A boiler can run on different fuels depending on availability and local legislation.

Greenhouse heating and cooling systems by Enerdes

For many climates, additional heating may be necessary in colder seasons, but additional cooling is necessary in the summer. Simply venting may not be enough to dispose of excessive heat and/or lower humidity levels.

Enerdes greenhouse climate control systems fully integrate both. Our systems save measured temperature and humidity data of your greenhouse and use them to anticipate the heating and cooling demand of your greenhouse. This leads to smooth temperature control in your greenhouse and constant temperature and humidity levels.